Jitong Intelligent provides a comprehensive environmental monitoring system for EVE Lithium Energy’s lithium battery production workshops. By deploying professional sensors and data acquisition gateways within the workshops, the system monitors environmental parameters in real time, including temperature, humidity, dew point, dust concentration, and harmful gases. At the same time, it remotely monitors related auxiliary production facilities through network connectivity, obtaining real-time operational status of the equipment to support the factory’s digital transformation.

The EVE Lithium Energy Jingmen HBC Factory Small Cylindrical Battery Production Line Expansion Project covers an area of 226 acres with a total investment of 3 billion RMB, achieving the construction of 130,000 square meters of high-standard factory buildings. The main products of this project are 18650 and 21700 cylindrical batteries. Upon reaching production, the annual output capacity is expected to reach 750 million units. The project has built six globally advanced high-speed production lines with a production efficiency of 300 ppm, achieving fully automated, stable, and efficient operation throughout the entire process. Following the requirements of the Lighthouse Factory program, the project adopts digital operation to realize lower carbon emissions.

Due to the rapid business growth of EVE Lithium Energy, various production workshops have been continuously expanded. However, the environmental conditions of each workshop are not centrally and uniformly managed. Management personnel cannot monitor the operating environment of each workshop and production process in real time. Once environmental conditions in a workshop become abnormal, it will affect the normal operation of production activities, causing business interruptions or untimely handling, resulting in potentially significant economic losses.

To address these potential risks, this project plans to build an environmental monitoring system at the Jingmen HBC Cylindrical Factory. The system will network environmental transmitters distributed across multiple workshops and processes to achieve centralized monitoring and unified management, providing decision-making support to optimize battery production quality and improve the production environment.

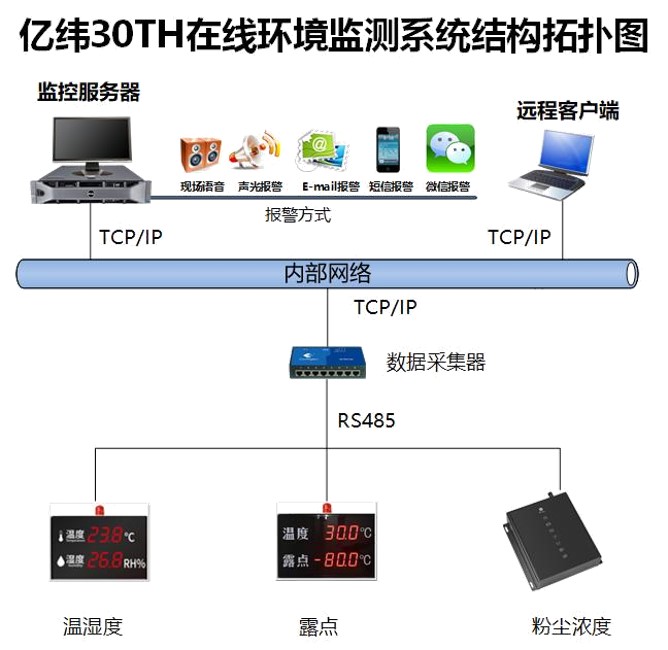

The online environmental monitoring system can be divided into three layers: the management application layer, the data acquisition layer, and the front-end device layer.

Management Application Layer: Composed of monitoring servers, environmental monitoring software, and databases, this layer centrally and uniformly monitors and manages data collected from front-end devices via the data acquisition layer.

Data Acquisition Layer: Responsible for aggregating and converting signals from front-end devices. It converts signals such as RS485 from front-end devices into TCP/IP signals for network transmission and supports local data collection, parsing, and storage.

Front-End Device Layer: Consists of various environmental sensors and intelligent devices connected to corresponding interfaces of the data acquisition layer via interfaces such as RS485. These devices collect environmental parameters and equipment operational status, which are then fed back to the central monitoring platform.

Real-time monitoring of frontline production environments

Intelligent early warning and alarm handling

Professional and flexible decision-making platform